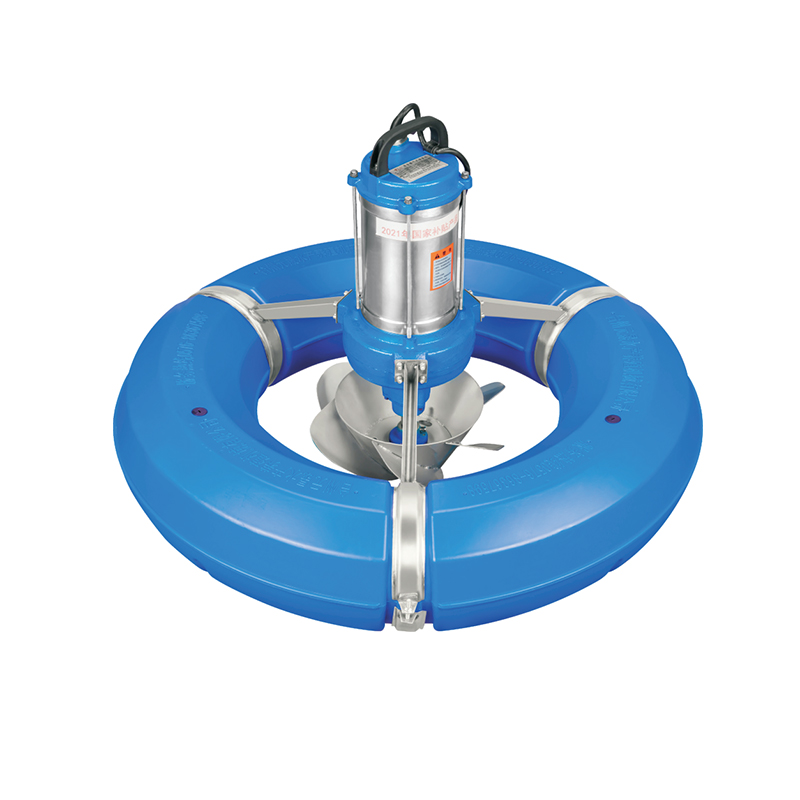

The Aquaculture Machine Aerator is proving to be a cornerstone component in modern aquaculture systems, especially for engineers and factory production teams tasked with integrating high-efficiency aeration into large-scale tanks or pond systems. New device generations exhibit significant advances in automation, sensor feedback and energy performance.

Aquaculture Machine Aerator Technology Advances and Industry Drivers

In recent years, aeration equipment used in aquaculture has moved past traditional paddle-wheel or coarse bubble systems towards models featuring fine-bubble diffusers, integrated real-time dissolved-oxygen monitoring, IoT connectivity and modular construction. The global aeration system segment in the aquaculture equipment market generated roughly USD 900 million in 2024 and is expected to grow annually at about 6 % through the forecast period. Industrial aerators broadly (including aquaculture) held a market value of USD 5.6 billion in 2024 and may rise to USD 9.7 billion by 2030 at a growth rate of 6.8 %.

These figures highlight strong demand for aerator innovations that reduce energy consumption while improving oxygen-transfer and circulation efficiency.

Aquaculture Machine Aerator Performance Metrics and Comparative Data

From a technical perspective important metrics include oxygen-transfer rate (kg O₂ per kW·h), circulation depth (metres of water column reached), power consumption (kW per unit) and mixing radius (m²). One research project showed a novel aeration device increased oxygen-transfer rate by 122 % compared to a conventional system in a recirculating aquaculture system (RAS) context.

When factory teams compare designs they may find that a fine-bubble diffuser system achieves ~1.8 kg O₂/kW·h under test, whereas an older paddle-wheel or coarse-bubble model registers around ~1.0 kg O₂/kW·h under similar conditions. For a given pond of 2 000 m² surface area and depth 1.2 m the difference in energy cost across the year becomes significant.

Aquaculture Machine Aerator Factory Implementation and Engineering Challenges

Factories manufacturing or assembling Aquaculture Machine Aerator equipment face multiple engineering tasks. They must ensure frame and floatation stability in dynamic pond environments, motor cooling in humid conditions, corrosion-resistant blade or diffuser materials, and ease of maintenance. For example, one design study found that flowrate, gate opening, hydrostatic level and plunge angle were the parameters most affecting aeration performance. At factory stage attention to gear-box quality, sealing, anchor structure and float buoyancy prevents early failure. Production teams also need to verify uniform mixing through the depth, avoid dead zones, and ensure even dissolved-oxygen distribution across the pond or tank. QA test rigs often simulate pond conditions and measure DO at various depths and locations.

Aquaculture Machine Aerator Technical Buyer Questions

What questions should technical procurement or R&D teams ask when evaluating an Aquaculture Machine Aerator for industrial use? Key queries include: what is the measured oxygen-transfer rate under defined conditions? What motor power and RPM is required? What coverage radius and depth is guaranteed? How is sensor feedback or remote monitoring implemented? Integration of IoT sensor networks is rising in popularity, enabling real-time tracking of dissolved oxygen, temperature and power consumption data.

Technical buyers should inspect factory test documentation, ask for long-term field-trial results and ensure the equipment is rated for the intended pond size, depth, stocking density and water quality conditions.

In conclusion, the Aquaculture Machine Aerator stands at the intersection of advanced engineering, factory production discipline and aquaculture operational needs. Engineers and technical buyers who align performance metrics, production reliability and system integration will secure aeration solutions that support health of aquatic species and operational efficiency into the future.

English

English 中文简体

中文简体 عربى

عربى