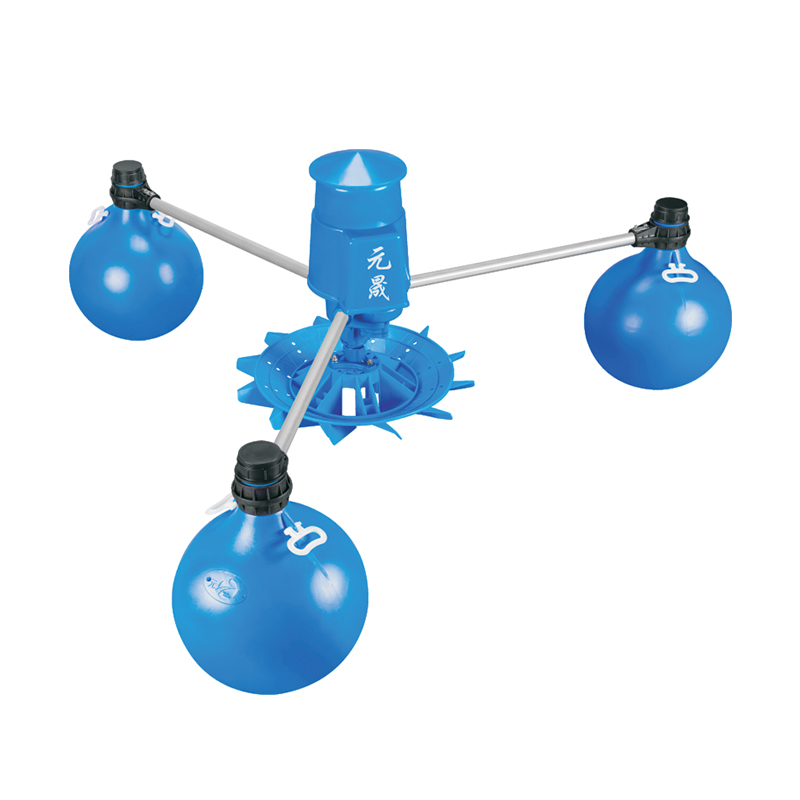

The Impeller Type Aerator has become a key choice for buyers managing aquaculture ponds and water treatment operations that require efficient oxygenation and mixing. As buyers explore solutions that balance performance, energy consumption, and coverage, understanding operational metrics and practical applications becomes critical. These systems also support improved water quality, reducing stagnant zones and promoting healthier aquatic environments.

Impeller Type Aerator Market Growth and Buyer Opportunities

Recent industry trends indicate that demand for impeller-type aerators continues to rise in aquaculture and water treatment sectors. Buyers now have access to more models and improved performance options, which allows for better alignment with specific operational requirements. Why should buyers focus on this type of aerator? The answer lies in its ability to combine high oxygen transfer with strong water circulation, supporting both intensive aquaculture and large-scale treatment systems. The increasing variety of designs also provides buyers with flexibility to match power requirements and pond dimensions more precisely.

Impeller Type Aerator Performance Metrics Buyers Should Know

Performance data are crucial for buyers evaluating aeration solutions. Impeller aerators can deliver oxygen transfer ranging from 1.0 to 1.8 kg per kW·h depending on model and operating conditions. Comparing these numbers helps buyers determine energy efficiency and operational cost. Another important factor is mixing depth: some units effectively circulate water in depths over 2 meters, ensuring oxygen reaches bottom layers and prevents stratification. Buyers need to evaluate both oxygen transfer efficiency and mixing capabilities to select the optimal system for their specific ponds or tanks.

Impeller Type Aerator Depth and Application Considerations for Purchase

Water depth and operational context significantly impact performance. In shallow ponds, aerators may efficiently oxygenate surface layers but leave bottom water under-aerated. In deeper ponds, vertical mixing improves but energy consumption increases. Buyers must consider pond or tank geometry, species requirements, and critical oxygen zones to avoid underperformance or unnecessary energy costs. Proper selection ensures the aerator meets both ecological and operational objectives. The flexibility in installation angles and impeller designs further enhances adaptability for complex pond layouts.

Impeller Type Aerator Versus Alternative Aeration Solutions

From a buyer’s perspective, evaluating alternatives is essential. Submersible aerators and bubble diffusers provide fine oxygen bubbles but may require different maintenance routines and may not mix water as effectively in deep areas. Impeller aerators generally offer more uniform coverage in high-density aquaculture ponds or treatment tanks. Buyers can weigh energy consumption, installation complexity, and operational coverage when comparing these options to ensure the chosen system fits their operational needs. The choice can directly affect dissolved oxygen stability and overall pond management efficiency.

Impeller Type Aerator Buyer Checklist and Practical Use Cases

Buyers should consider several key factors when selecting an impeller aerator:

- Efficiency in kg O₂/kW·h

- Suitable water depth and mixing radius

- Power consumption and expected operating costs

- Ease of maintenance and blade durability

Installation footprint and compatibility with pond or tank layout

Practical applications demonstrate that high-density aquaculture operations benefit from consistent dissolved oxygen, reduced risk of stress for aquatic species, and improved pond management. Water treatment facilities can use impeller aerators to reduce dead zones, increase circulation, and maintain uniform oxygen levels. Their versatility also allows adaptation to changing operational demands and seasonal variations in water conditions.

In conclusion, the Impeller Type Aerator provides buyers with an effective combination of oxygen transfer, depth mixing, and operational flexibility. By carefully considering performance metrics, water depth, and application requirements, buyers can select a system that supports both ecological health and operational efficiency, making it a strategic choice for aquaculture and water treatment management.

English

English 中文简体

中文简体 عربى

عربى