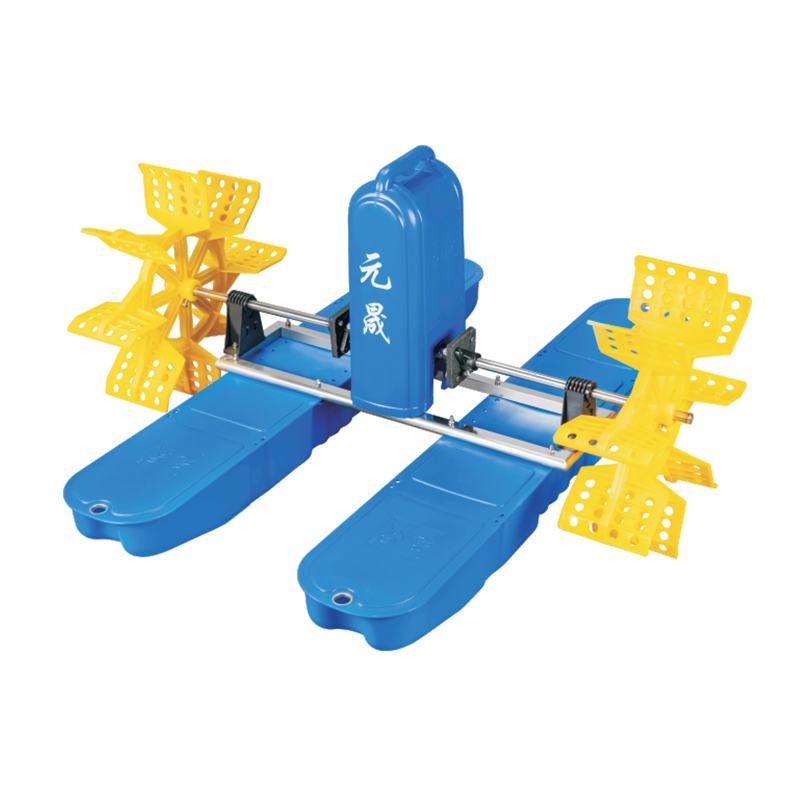

Aquaculture has become one of the fastest-growing food sectors globally, driven by the rising demand for seafood and sustainable protein sources. At the heart of any successful fish or shrimp farming operation is a critical component: the aquaculture machine aerator. This device is designed to maintain ideal water conditions, primarily by increasing the oxygen levels essential for aquatic life.

The primary function of an aquaculture machine aerator is to infuse oxygen into water bodies. In densely stocked ponds, oxygen depletion can occur rapidly, especially during the night or in overcast conditions. Without a proper aquaculture machine aerator, the water can become hypoxic, leading to stress, disease outbreaks, and even mass die-offs.

A high-performance aquaculture machine aerator not only improves oxygenation but also enhances water circulation. This movement helps distribute nutrients evenly, prevents thermal stratification, and promotes the breakdown of organic waste. The result is a healthier environment that supports higher stocking densities and faster growth rates.

There are various models of aquaculture machine aerator systems available to suit different farm setups. Surface aerators are excellent for shallow ponds and surface-level oxygen needs. Subsurface or diffused air systems are more suitable for deep tanks or RAS operations. Some farms even combine multiple aerators to achieve optimal performance across large or segmented water bodies.

Using an aquaculture machine aerator has direct economic benefits. Better oxygen levels mean fish and shrimp can metabolize feed more efficiently, reducing feed costs. Additionally, fewer disease outbreaks mean lower veterinary expenses and less reliance on antibiotics or chemicals. This translates into higher yield and better product quality, both of which are crucial for market competitiveness.

One of the key challenges farmers face is balancing oxygen needs with energy costs. Fortunately, many aquaculture machine aerator units now come equipped with features that support energy efficiency. Variable speed motors, timers, and automated sensors ensure that aeration occurs only when necessary. These smart features reduce operating costs without compromising water quality.

Maintenance is also a factor that contributes to the reliability of an aquaculture machine aerator. With proper care—like checking motor function, cleaning aeration heads, and replacing worn-out parts—these machines can last for many years. Many farmers establish a routine schedule to inspect and service their aerators, recognizing that downtime could lead to catastrophic losses.

As aquaculture continues to evolve, so does the design of the aquaculture machine aerator. Newer models incorporate corrosion-resistant materials, noise-reducing technologies, and even remote monitoring capabilities. This makes it easier for farmers to oversee operations, especially in large or multi-pond setups.

Besides traditional aquaculture, the aquaculture machine aerator is finding applications in eco-farming, water treatment, and research institutions. Its ability to restore oxygen levels and prevent water stagnation makes it valuable beyond just fish farming.

Environmental sustainability is another reason to invest in a good aquaculture machine aerator. By maintaining clean and oxygen-rich water, farms reduce their ecological footprint, comply with regulatory standards, and support biodiversity. In many cases, effective aeration reduces the need for frequent water changes, conserving water resources.

The aquaculture machine aerator is not just a piece of equipment—it’s the backbone of a healthy and productive aquaculture system. Whether you are running a small backyard pond or a large commercial facility, having a reliable aquaculture machine aerator ensures your operation thrives, your animals stay healthy, and your bottom line improves.

English

English 中文简体

中文简体 عربى

عربى