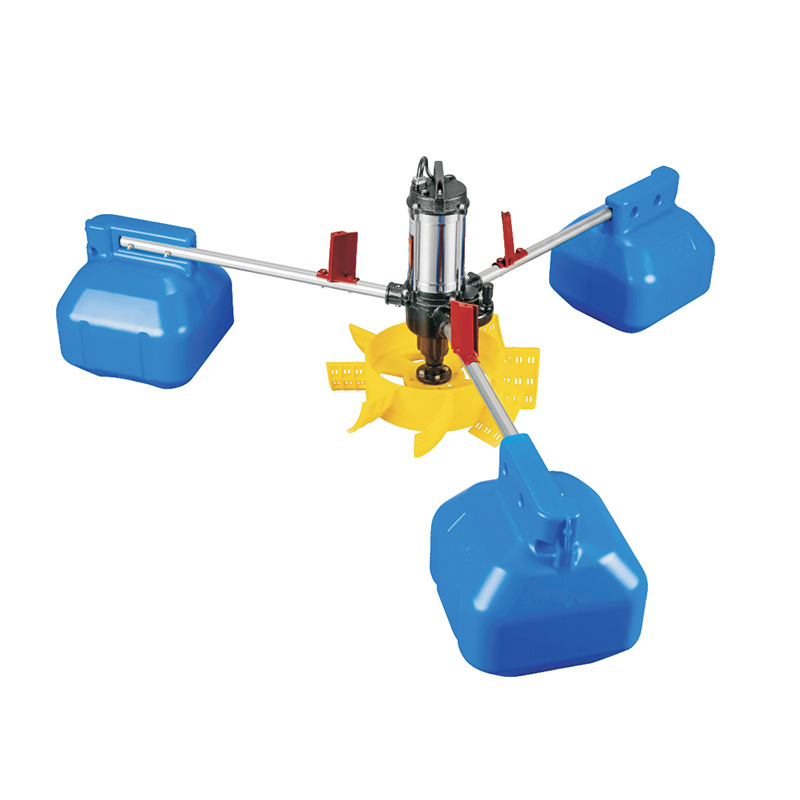

Impeller type aerators are increasingly utilized in water management and aquaculture due to their unique method of oxygenating water. These devices employ a rotating impeller to move water, generating both surface splashes and underwater currents. This dual action facilitates oxygen transfer from air to water while promoting uniform water circulation. Studies have shown that a well-designed impeller aerator can increase dissolved oxygen levels by up to 60% in medium-sized ponds within a 24-hour period under optimal conditions.

The impeller design is central to the aerator’s efficiency. Modern impellers often feature multiple blades arranged at specific angles, enhancing water displacement and energy loss. The movement of water created by the impeller not only introduces oxygen but also disrupts stagnant layers, which can accumulate harmful gases like ammonia and hydrogen sulfide. In aquaculture environments, maintaining even oxygen distribution is critical for fish and shrimp health, as uneven oxygen levels can affect growth rates and increase mortality risk.

Energy consumption is another important consideration. Impeller-type aerators are designed to use energy efficiently while maintaining consistent oxygen transfer. Smaller units can operate efficiently at 1.5 to 3 kW, achieving oxygen transfer rates of approximately 3.5 to 5 kg per kilowatt-hour. This efficiency makes them suitable for long-term operation in ponds and lakes without significant increases in electricity costs. Operators often report that careful positioning of the aerator within the water body can further improve energy efficiency by reducing the formation of low-circulation zones.

Applications of impeller aerators are diverse. In aquaculture, they are frequently used in fish and shrimp ponds to support healthy water conditions. Beyond aquaculture, these aerators are also effective in small lakes and ecological water bodies, where water circulation and aeration help maintain water quality. In some cases, combining multiple aerators in a large water body can create extensive circulation patterns, reducing sediment accumulation and improving overall water clarity.

Despite their benefits, proper maintenance is necessary to ensure long-term operation. Impellers should be inspected for wear, and motors should be checked for waterproofing integrity. Operators also need to monitor dissolved oxygen levels regularly to confirm that the aerator maintains target oxygen concentrations.

FAQ

Q: How often should an impeller aerator be operated?

A: Operation depends on water temperature and oxygen demand, but continuous operation during warm months is common to maintain adequate oxygen levels.

Q: Can impeller aerators handle large ponds effectively?

A: Yes, when properly sized and positioned, they can circulate water over several hectares, although larger water bodies may require multiple units.

Q: What maintenance is required for the impeller?

A: Routine inspection for wear, removal of debris, and checking the motor’s waterproof seals are recommended to maintain efficiency.

Q: How quickly does water oxygenation occur?

A: Dissolved oxygen levels can increase noticeably within hours, but full uniform oxygenation in medium ponds may take up to 24 hours.

Impeller type aerators serve as an effective approach to enhancing water quality and maintaining consistent oxygen levels throughout ponds and small lakes. Their operation relies on carefully engineered impellers that generate strong water movement, which helps prevent stagnant zones and distributes oxygen evenly. Efficient energy usage allows these aerators to operate for extended periods without creating excessive electricity costs, making them suitable for continuous application during warm seasons when aquatic life has higher oxygen demands.

English

English 中文简体

中文简体 عربى

عربى