Impeller type aerators are increasingly utilized in water management and aquaculture due to their unique method of oxygenating water. These devices employ a rotating impeller to move water, generating...

Product Category:

Product:

We can save cost and create value for you

Aquaculture Machine Aerator Factory

-

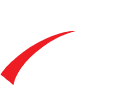

Floating Oxygenator (Sea Water Type)

-

Fully Automatic Floating Aerator

-

Surge Aeration Type Oxygenator

-

Super Impeller Type Oxygenator

-

Impeller Type Oxygenator

-

Variable Frequency Impeller Aerator

-

Gearless Impeller Type Oxygenator

-

High-Performance Water Wheel Aerator (Water-Cooled)

-

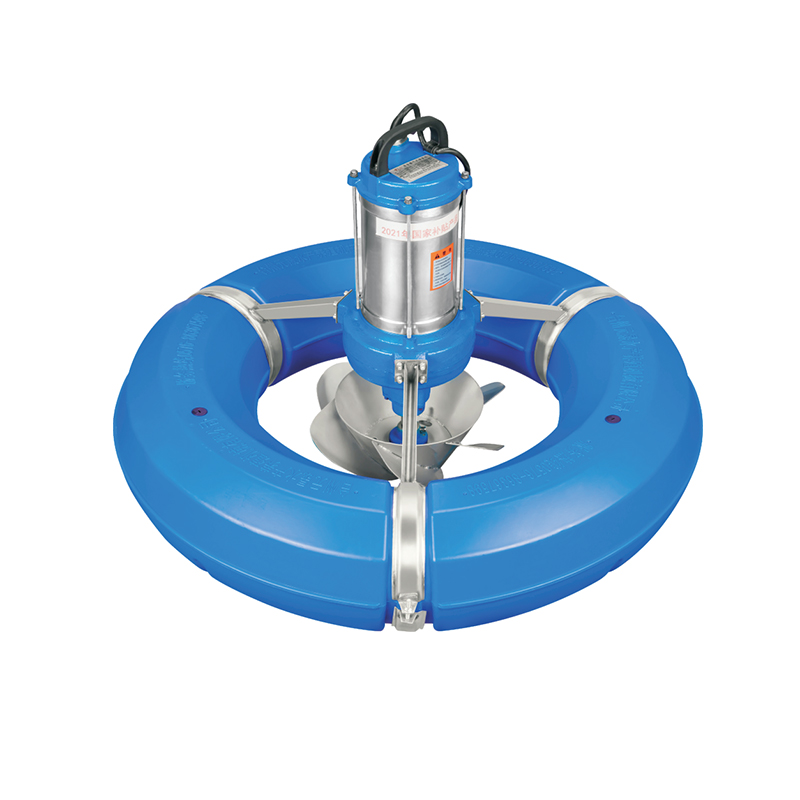

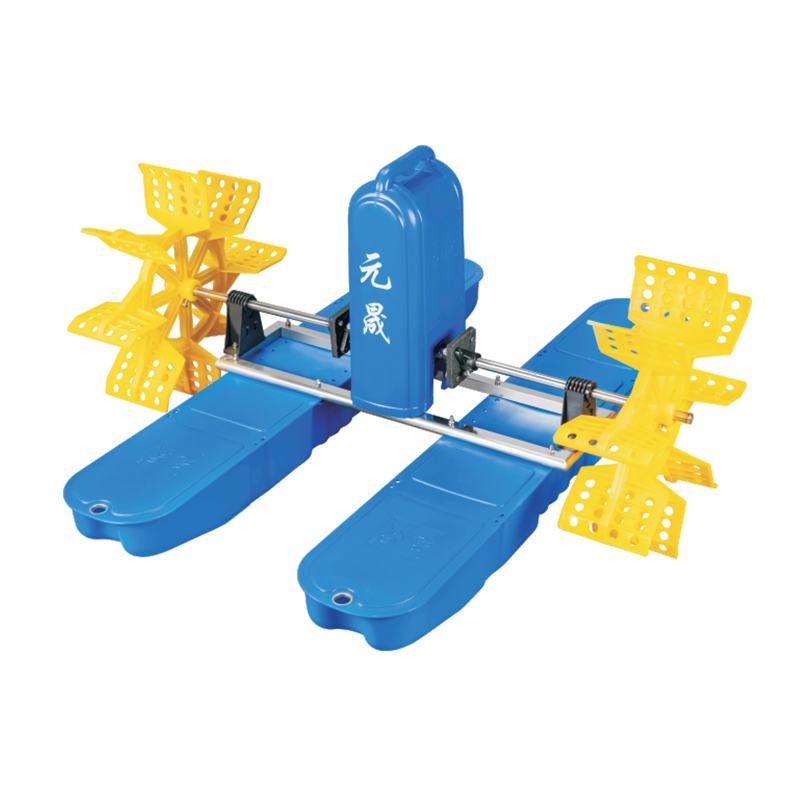

Water Wheel Aerator

-

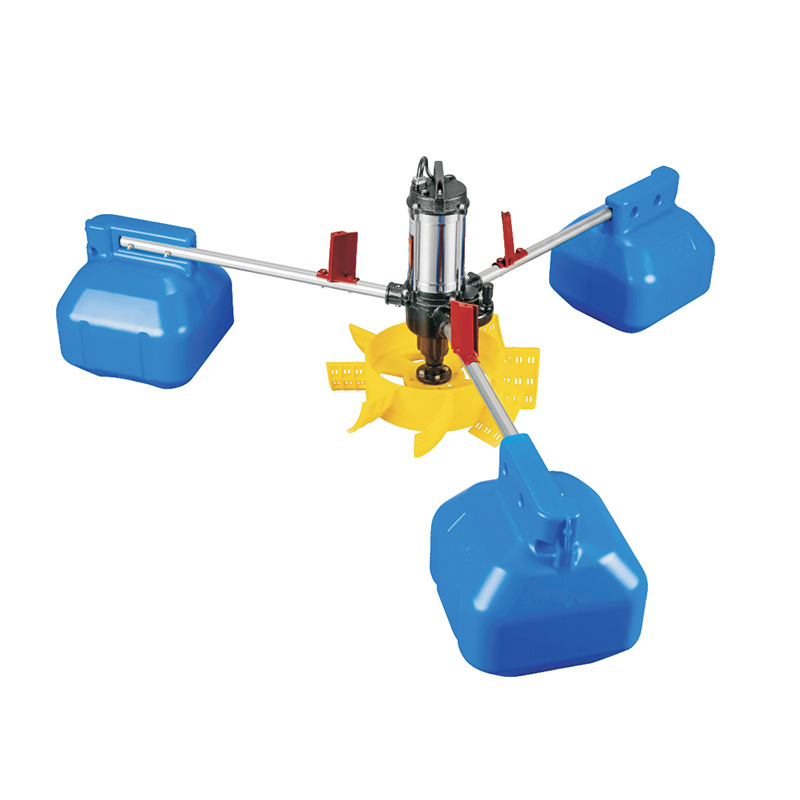

Y Series Fully Automatic AC/DC Dual-Purpose Aerator

In the world of aquaculture, maintaining optimal water quality is essential for the health and growth of aquatic organisms. One key piece of equipment that contributes to this is the aquaculture mechanical aerator. These devices are designed to increase oxygen levels in water, which is crucial for fish, shrimp, and other aquatic species. Mechanical aerators achieve this by agitating the water, facilitating oxygen exchange, and promoting the overall health of the aquaculture environment. This article will explore the advantages, features, and applications of the aquaculture mechanical aerator.

Advantages of Aquaculture Mechanical Aerators

Improved Oxygenation

One of the primary advantages of mechanical aerators is their ability to effectively increase the dissolved oxygen (DO) levels in water. Fish and other aquatic organisms rely on oxygen for survival, and when the oxygen levels drop, it can lead to stress, reduced growth rates, or even fatalities. Mechanical aerators continuously mix the water, enhancing oxygen exchange between the water and air, ensuring that aquatic life thrives.

Enhanced Water Circulation

Mechanical aerators help promote water circulation, which is essential in preventing stagnation. Stagnant water can lead to the buildup of harmful substances, such as ammonia or carbon dioxide, which are detrimental to aquatic life. By improving water flow, mechanical aerators create a healthier and more dynamic environment, reducing the risk of water quality issues.

Increased Productivity

By ensuring a constant supply of oxygen, mechanical aerators enhance the overall productivity of aquaculture operations. Fish and other aquatic organisms grow more efficiently in well-oxygenated water, leading to higher yields. Additionally, the reduction of waterborne diseases and the prevention of oxygen-related stress result in better survival rates, contributing to increased productivity.

Energy Efficiency

Modern mechanical aerators are designed to be energy-efficient, ensuring that they provide adequate oxygenation without consuming excessive power. With advancements in motor and blade technology, these aerators can maintain high performance while keeping energy costs manageable, making them an economically viable option for large-scale aquaculture operations.

Features of Aquaculture Mechanical Aerators

Durable Construction

Aquaculture mechanical aerators are built to withstand harsh environmental conditions. Made from corrosion-resistant materials such as stainless steel or high-quality plastics, they can operate efficiently in both fresh and saltwater. Their durable construction ensures a long service life, reducing the need for frequent maintenance or replacements.

Adjustable Speed and Flow Control

Many modern mechanical aerators come with adjustable speed and flow controls, allowing operators to tailor the aeration process to the specific needs of their aquaculture system. Whether the goal is to increase oxygenation during peak feeding times or to adjust for different water volumes, these controls offer flexibility in operation.

Low Noise Operation

While older aerators could be quite noisy, modern mechanical aerators are engineered to operate quietly. This is particularly beneficial in aquaculture environments where noise pollution can stress fish or disturb the overall operation. Low-noise designs ensure that the aerator runs efficiently without disrupting the aquatic life or the surrounding environment.

Self-Priming and Easy Maintenance

Many mechanical aerators are designed to be self-priming, meaning they can begin operating automatically without the need for manual intervention. Additionally, they are typically low-maintenance, with easily accessible parts for routine cleaning or inspection. This feature reduces downtime and operational costs, ensuring continuous performance.

Applications of Aquaculture Mechanical Aerators

Fish Farming

Mechanical aerators are extensively used in fish farming, particularly in ponds and tanks. Oxygen is critical for fish health, and these aerators ensure that fish, including species like tilapia, salmon, and trout, receive the necessary oxygen to grow and thrive. Aerators are especially important in high-density farming systems, where oxygen consumption can be very high.

Shrimp Farming

In shrimp farming, the role of mechanical aerators is crucial for maintaining water quality. Shrimp are highly sensitive to oxygen levels, and mechanical aerators help ensure that the water remains oxygen-rich, facilitating healthy shrimp growth and improving overall productivity in shrimp farms.

Hatcheries

Aquaculture hatcheries rely on mechanical aerators to maintain optimal water quality for the early stages of aquatic organisms’ development. In hatcheries, it is especially important to have a steady oxygen supply for the larvae and juvenile fish or shrimp, as their delicate stages of growth are highly vulnerable to fluctuations in water quality.

Recirculating Aquaculture Systems (RAS)

Mechanical aerators are integral components of recirculating aquaculture systems, which are becoming more common in land-based fish farming. These systems reuse water by filtering and aerating it before it’s returned to the tanks. Aerators help keep the water oxygenated and ensure that fish in these closed-loop systems remain healthy.

Pond and Lake Aquaculture

In larger-scale pond or lake aquaculture, mechanical aerators are used to increase oxygen levels in the water, especially in areas with high stocking densities. They help prevent the formation of dead zones, which can occur in deep ponds where oxygen levels are naturally lower. The aerator’s ability to circulate and oxygenate large volumes of water is essential in sustaining a healthy aquaculture environment.

Water Quality Management

Mechanical aerators are also used for water quality management in natural water bodies, including lakes and reservoirs, that are being used for aquaculture purposes. These aerators help control the buildup of harmful substances, such as methane and hydrogen sulfide, which can occur in oxygen-deprived waters, thus promoting a more stable and healthy environment for aquaculture.

Aquaculture mechanical aerators are indispensable tools in modern aquaculture, playing a crucial role in maintaining water quality and supporting the health of aquatic organisms. Their ability to improve oxygen levels, enhance water circulation, and increase productivity makes them an essential investment for fish and shrimp farmers alike. With durable construction, energy-efficient operation, and flexible features, these aerators are well-suited for a wide range of aquaculture applications, from hatcheries to large-scale fish farms. As aquaculture continues to expand, the demand for reliable and efficient mechanical aerators will only grow, solidifying their place as a cornerstone of successful aquaculture operations.

Taizhou Yuansheng Aquacul Ture Machinery Co., Ltd.

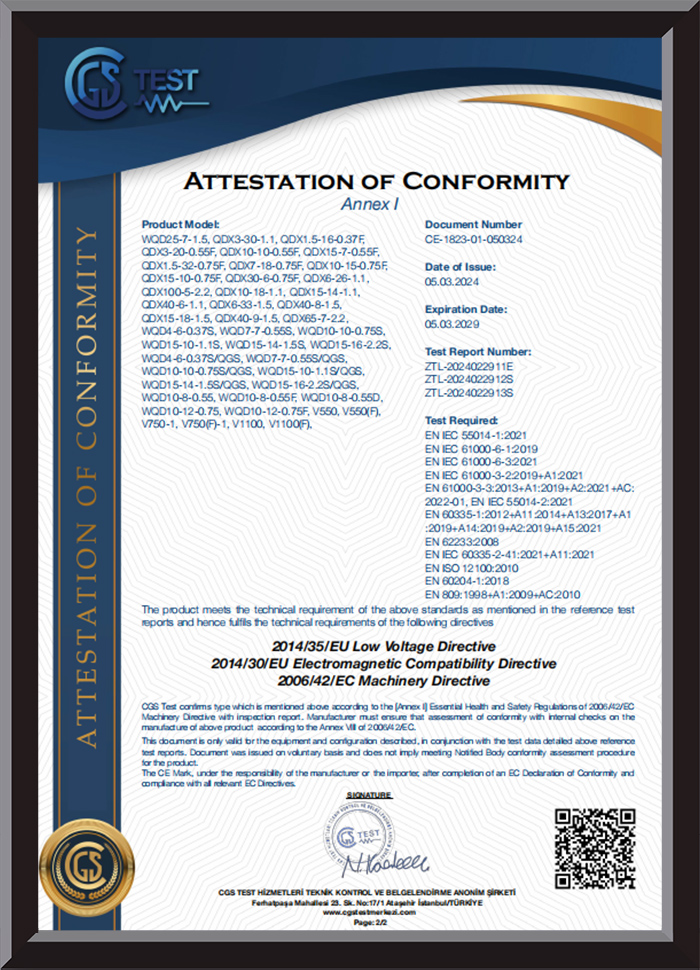

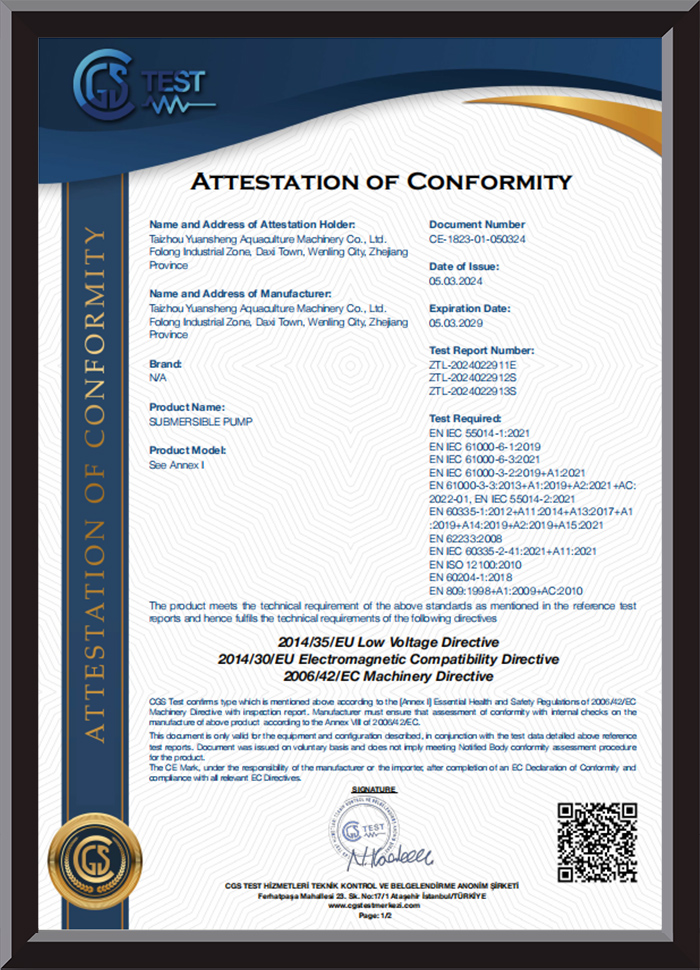

Certificate of Honor

OUR LATEST NEWS

-

How Does an Impeller Type Aerator Improve Water Quality?

Read More -

How Does a Surge Wave Aerator Work?

Read MoreA surge wave aerator is a water aeration device designed to improve oxygen levels in ponds, tanks, and other aquatic systems by using specialized structural designs. At the core of its operation is th...

-

Modern Solar Panel Aerators

Read MoreSolar panel aerators have seen significant development in recent years, offering versatile designs that support sustainable agriculture and water management in remote locations. Modern models prioriti...

-

How to Choose a Float Type Aerator

Read MoreIn recent years, the use of the Float Type Aerator has steadily expanded across aquaculture, water quality management, and ecological restoration projects. Unlike compressed air diffusion systems, flo...

English

English 中文简体

中文简体 عربى

عربى